In the context of the global construction industry's continuous pursuit of construction efficiency, structural consistency, and cost control, the tunnel formwork system has gradually become the mainstream formwork solution for highly repetitive construction projects. This system is widely used in residential buildings, apartments, dormitories, and affordable housing projects, and is particularly suitable for building types with a high degree of standardisation and relatively regular structures.

This article will systematically analyse the tunnel formwork system from aspects such as its definition, working principle, system composition, main types, applicable scenarios, and supplier selection, helping engineering decision-makers better understand the value of this construction system in modern architecture.

What is a Tunnel Formwork System?

A tunnel formwork system is a system formwork construction method that combines wall formwork and slab formwork into an integrated structure. During construction, the walls and slabs can be cast in a single construction cycle, forming a concrete unit similar to a "tunnel," which is where the system gets its name.

Compared with traditional phased construction methods, tunnel formwork can significantly improve the construction pace, reduce uncertainty in the process, and ensure the consistency of concrete structure quality. Globally, tunnel formwork is considered a typical application of system formwork.

GETO has successfully launched its tunnel formwork, which balances construction convenience, overall cost, and product turnover rate, achieving a balance between construction cost, construction efficiency, and construction technology. It is also the fastest and most economical way to build high-quality earthquake-resistant apartments, villas, student dormitories, and hotels.

Working Principle of the Tunnel Formwork System

The core logic of the tunnel formwork system lies in "structural integration" and "construction standardisation." In each construction cycle:

- The formwork system is installed as a whole.

- Wall and slab reinforcement are tied simultaneously.

- Concrete is cast in a single pour.

- The formwork is demolded as a whole after the specified time and moved to the next construction unit.

This process makes the construction pace highly predictable, making it very suitable for fast-paced, large-scale engineering projects.

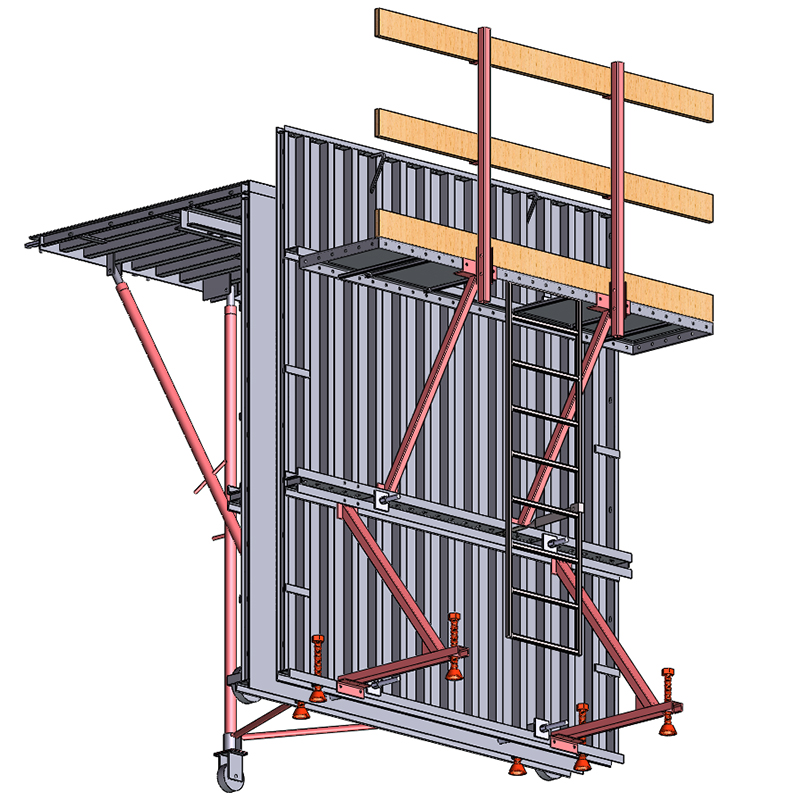

Tunnel Formwork Components

The tunnel formwork system mainly consists of a formwork system, a support system, and a connection system, supplemented by lifting platforms (bay platforms, stairwell platforms, elevator shaft platforms) and external wall working platforms as auxiliary systems.

These tunnel formwork components together constitute a reusable, systematic formwork structure. Its modularity directly affects construction efficiency and the difficulty of on-site management.

Main Types of Tunnel Formwork Systems

Based on different materials and structural forms, tunnel formwork systems are mainly divided into the following two categories:

Aluminium Tunnel Formwork

Aluminium tunnel formwork is characterised by its lightweight design, combined with high strength and good reusability. The main body is an integrated aluminium formwork.

Its advantages include:

- Fast overall installation speed.

- High standardisation, and high material reuse rate, with a wide range of application areas.

- Flexible assembly and disassembly, simple process, reduced labour input, relatively low cost, and high safety performance.

- High scrap value of aluminium material.

- Lower deadweight and smaller crane specification requirements.

- Seamless integration with the quick deck concept, high turnover rates.

Steel Tunnel Formwork

Steel tunnel formwork is known for its structural strength and stability, and is usually used in building structures with high load-bearing requirements or large spans. The main body is a monolithic steel formwork.

Its advantages include:

- Simple formwork erection process, low labour force.

- Tightly spliced, not easy to deform

- Good integrity of formwork, strong seismic resistance,

- Good insulation performance, conducive to winter concrete insulation.

- Large formwork dismantling with a high level of mechanisation.

Aluminium Tunnel Formwork Installation – Step-by-Step Operational Flow

In practical engineering projects, the construction efficiency of aluminium tunnel formwork largely depends on standardised and regulated assembly procedures. Based on common engineering practices, its assembly and installation typically follow these steps:

|

Step |

Description |

|

Step 1 |

Familiarize with the drawings and arrange for someone to transfer materials to avoid confusion. |

|

Step 2 |

Preparation of assembling site, in order to protect the formwork from being scratched and the flatness of the surface, place the square wood at an interval of 50mm, to ensure that the formwork can be elevated. |

|

Step 3 |

Assemble the wall formwork and fix it temporarily with bolts and corresponding nuts and spacers. |

|

Step 4 |

Assemble the deck formwork and side formwork. |

|

Step 5 |

Connect the deck formwork, wall formwork, and side formwork, on the basis of acceptance completion, utilize slab corner joint and carry out connection work. |

|

Step 6 |

The keel and truss are installed and connected using the aluminium formwork connecting L-type movable tie rod. |

|

Step 7 |

Deck panel lifting and water installation. |

|

Step 8 |

Open lifting eyelets, acceptance and number formwork. |

|

Step 9 |

Construct by hoisting ready-built components into place. |

Core Advantages of the Tunnel Formwork System

From an engineering practice perspective, the main advantages of the tunnel formwork system are reflected in the following aspects:

Walls and floor slabs are cast in one go, improving structural consistency.

Stable construction cycle, facilitating project schedule management.

Reduced on-site procedures, contributing to improved safety.

Suitable for large-scale, repetitive building construction.

Specific advantages may vary depending on the project type, structural design, and construction organisation methods, and usually require evaluation based on specific engineering conditions.

Typical Application Scenarios of the Tunnel Formwork System

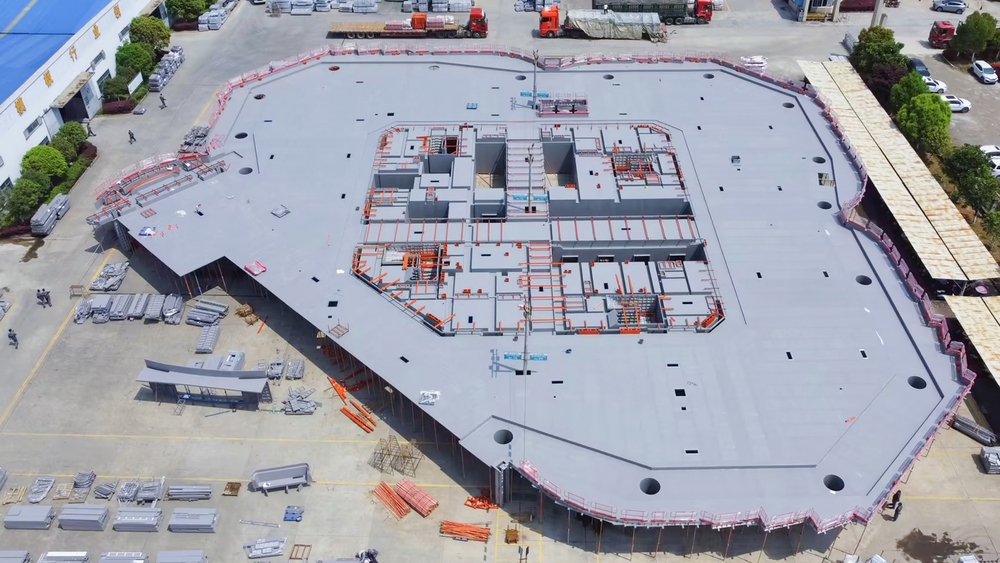

Tunnel Formwork System Application

Tunnel formwork systems are commonly used in the following building types:

- High-rise or medium-high-rise residential buildings

- Student dormitories, worker dormitories

- Social housing

- Apartment hotels

These projects generally feature a high degree of structural standardisation and a large number of repetitive units, which highly aligns with the construction logic of the tunnel formwork system.

How to Choose a Suitable Tunnel Formwork Supplier

In actual engineering projects, the construction effect of the tunnel formwork system depends not only on the system itself but also on the supplier's systematic capabilities. Therefore, when choosing a suitable system formwork supplier or tunnel formwork manufacturer, the following aspects should be considered:

- Whether they have a complete system formwork product range

- Whether they can provide standardised tunnel formwork components

- Whether they possess engineering, detailed design and technical support capabilities

- Whether they have experience in similar projects

- Whether they have stable production and delivery capabilities

In the international market, companies like Geto Formwork, which can provide systematic solutions and have experience in overseas projects, are often better able to adapt to the engineering needs of different regions.

Conclusion: The Value of the Tunnel Formwork System in Modern Construction

With the improvement of industrialisation and standardisation levels in the construction industry, the tunnel formwork system is becoming an important construction method in residential and repetitive building projects. Whether it's Aluminium Tunnel Formwork or Steel Tunnel Formwork, its core value lies in improving construction efficiency and quality control through systematic design.

For engineering decision-makers, understanding the technical characteristics of tunnel formwork, combined with project conditions and choosing a suitable system formwork supplier, will be more conducive to achieving a balance between safety, schedule, and cost for the project.