In modern construction projects, shoring systems are a crucial component for ensuring the safety, efficiency, and quality of building structures. Whether it's cast-in-place concrete structures, bridge engineering, or large public buildings, the rational selection and application of support systems are key aspects of construction organization and design. This article will systematically review common types of shoring systems, their functional logic, and selection considerations from a practical engineering perspective, helping project managers better understand the application value of various shoring solutions in different scenarios.

Types of Geto Shoring Systems in Construction Projects

Ringlock Scaffold Shoring Systems

Ringlock Scaffold Shoring Systems Application

The ringlock scaffolding system is mainly used to support bridge projects, tunnel projects, factory buildings, elevated water towers, power plants, oil refineries and other special factories, and can also be used in projects such as crossing bridges, cross beams, storage shelves, large stages and background frames.

It includes M48 and M60 standards, lengths ranging from 500mm to 3000mm, and the main materials are steel Q345 and Q235.

The 48mm system is mainly applied to civil construction projects, operating platforms, etc. (construction projects with relatively small loads). The 60mm system is mainly applied to municipal engineering, cast-in-place beams for rail transit, swivel bridges, freight viaducts, etc. (construction projects with relatively large loads)

Advantages

- Strong carrying capacity: the carrying capacity of a single pole is up to 19 tons (60 series).

- Safe and reliable: The hot-dip galvanizing anti-corrosion process ensures a long service life.

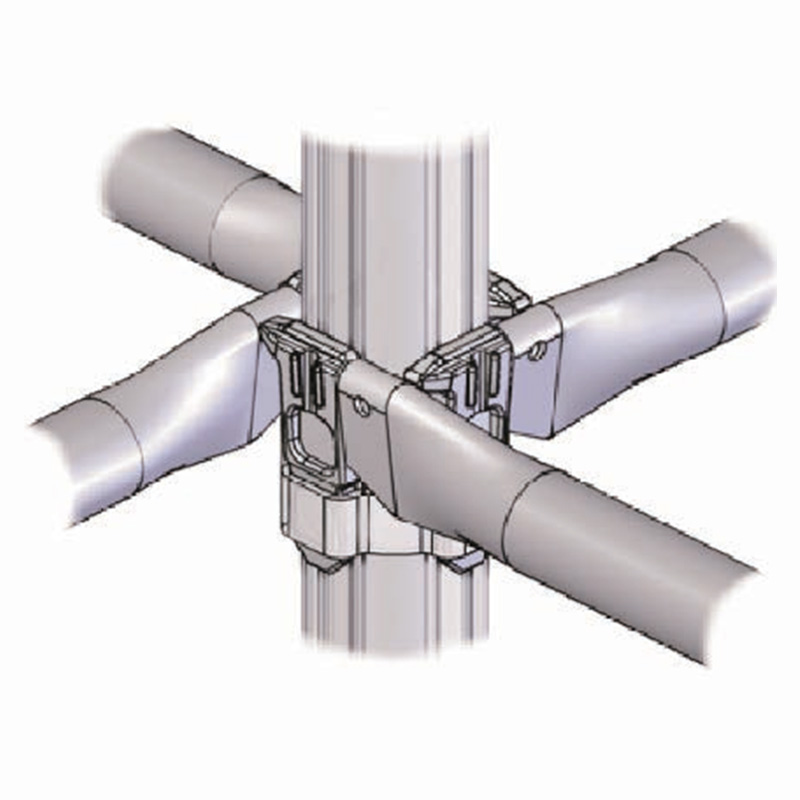

- Quick assembly: The unique design of the disc self-locking plug improves construction efficiency.

- Economical and practical: Less steel consumption and lighter weight reduce transportation and labor costs.

H-Frame Shoring System

H-Frame Scaffolding is a kind of scaffolding that is widely used in buildings, halls, bridges, viaducts, tunnels, etc., or as the main support of table formwork. It is used in structural parts of buildings, such as structural frames, stair railings, roof supports, etc.

Advantages

It can also be used as internal and external grid scaffolding of high-rise buildings.

This kind of scaffold is mainly composed of the main frame, transverse frame, cross brace, scaffold board and adjustable base.

Surface: Pre-galvanized, hot-dipped galvanized, painted, powder coated

Main Components: Frame, cross brace, joint pin, catwalk, base jack, U head jack and castor.

Tower Support System

Tower Support System Application

Tower supports are assembled truss formwork supports with a height of up to 22.9 meters and above. Modular tower support with high load-bearing capacity.

Industrial plant/ warehouse (large span), airport project, metro station/ large-span integrated pipe gallery, box girder (thickness ≤2.0m, such as expressway box girder), large shopping mall/office building (large span, beamless system is more suitable), large basement (large span, beamless system).

Advantages

- Only 5 components, convenient for logistics and management

- Comprehensive Lighting Adjustments for Diverse Needs Quickly overlap, no need to design in advance.

- Modular assembly, convenient installation, high efficiency of assembly and disassembly

- The height can reach 25 meters.

- Lower cost

Steel Prop

The steel prop is a structure used to support the floor slab, which plays a supporting and bearing role in the process of concrete pouring and shaping.

Aluminum Beam Shoring System

Aluminium alloy I-beam ( Aluminium beam) is mainly used to support and strengthen the building structure, which can bear certain loads, and improve the stability and safety of buildings. Generally, the aluminium beam is marked with 6061, and 6063 is also sometimes used. The hardness and tensile strength of aluminium alloy vary with its state. It is usually used with aluminium formwork, conventional formwork and plastic formwork.

Advantages

- Lightweight with strong carrying capacity: Aluminum beams, with low density, lightweight, high strength, and great carrying capacity, are stronger and more stable than traditional steel-wood keels.

- Corrosion resistance: Aluminum beams have good corrosion resistance and are not prone to rust, making them suitable for use in harsh environments such as dampness, acids, and alkali.

- Easy processing: Aluminum beams are easy to process and install, allowing for cutting, drilling, welding, and other processing treatments as needed.

- Environmental protection and energy saving: The production process of aluminium beams does not generate pollutants and can be recycled and reused, meeting the requirements of environmental protection and energy saving.

Modular Building Shoring System

Modular Building Shoring System

The Modular Building Shoring System is widely used in modular construction and bridge engineering. With both the base and top props designed with telescopic rods, it offers a wide adjustment range and excellent stability. This system is especially suitable for early stripping conditions in building construction and complex foundation conditions.

In the Modular Building Shoring System, the standards have a diameter of 83 mm, a wall thickness of 2 mm, and are made of Q355B steel. Compliant with European standards.

Advantages

- High Load Capacity: Single standard supports up to 190 kN with strong stability.

- Flexible Design: Multiple ledger sizes for various support spacings.

- Durable and Low-maintenance: Fewer parts, hot-dip galvanized for long-lasting performance.

- Easy Assembly: Quick installation with secure connections and braces.

Truss Shoring System

Truss Shoring System Application

Truss Shoring System is widely applied in projects with complex engineering conditions, particularly in cast-in-place box girder formwork for uneven terrains, bridge reinforcement and dismantling works, heavy-load concrete casting support, gantry-type supports spanning roads and rivers, and steel structure erection.

It is especially well-suited for applications involving road and river crossings, irregular topographies, and extra-high shoring requirements.

In the Truss Shoring System, the standards have a diameter of 133 mm and a wall thickness of 5.6 mm, and are made of Q355B structural steel.

Advantages

- High Load Capacity: Single standard supports up to 450 kN.

- Flexible Spacing: Multiple ledger sizes for various support intervals.

- Excellent Overall Stability

- Single truss units provide high strength and rigidity.

- Quick Assembly:Fewer components, easy to install and dismantle; supports ground preassembly and hoisting.

- Adjustable Base Jacks: Adaptable to varying terrain conditions

Formwork Bracing Rib System

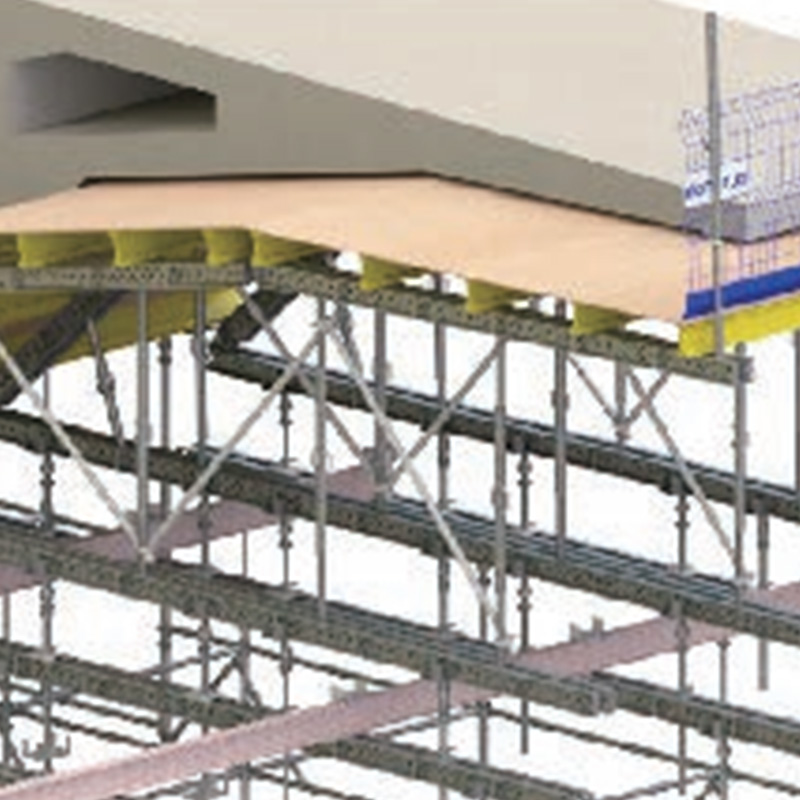

Formwork Beam System includes the aluminium beam system and double U-steel system, compatible with other supporting systems in the same series.

This system accommodates various support spacings, ensuring a large spacing support design while maximizing material efficiency. The aluminum beam and double U-steel systems serve as the top framework for support systems, offering high strength and rigidity.

Advantages of Aluminium Beams

Lightweight and High Strength: Made from 6005A-T6 material with a large design span, up to 2.4m.

Spliceable for Extended Use: It can be easily extended, with flexible adjustment on-site, and quick assembly and disassembly.

Strong Compatibility: Compatible with various special components and I-beams.

Effective Fixation: It can be securely fixed with other distribution beams.

Advantages of Double U-Steel Beams

Lightweight and High Strength: Made from Q355B material, offering strength with reduced weight.

Full-length Bolt Holes: Enables splicing and extension based on structural needs.

Bolt-connected Extension: Pre-assembled beams for easy and fast installation.

Strong Compatibility: Can be connected with guardrails for a protective system

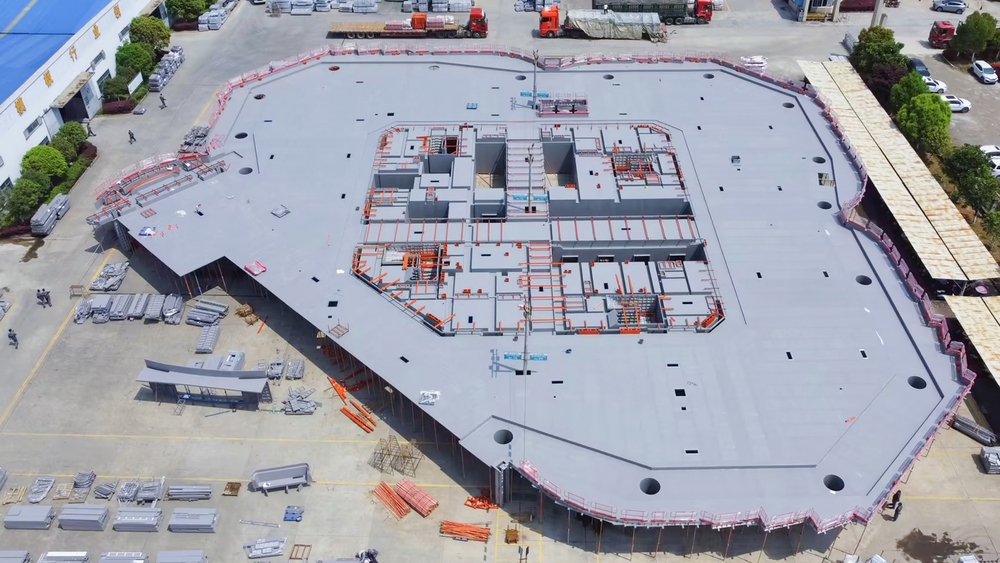

Duralok Shoring System

The Duralok Shoring System is widely applied in various fields, including airport construction, railway engineering, highway bridges, metro depots and stations, water conservancy and hydropower projects, as well as general building construction. Compared with conventional products, this system significantly reduces material consumption, optimizes on-site space utilization, alleviates transportation pressure, and improves overall construction efficiency.

In the Duralok Shoring System, the standards, ledgers, and diagonal braces all have a diameter of 48.3mm, a wall thickness of 3.2mm, and are made of Q355B steel. Compliant with European standards.

Advantages

Forged Nodes, Stronger Load Capacity

Rotational stiffness exceeds 100 kN·m/rad; each standard supports up to 120 kN, ensuring greater structural stability.

Diagonal Bracing, Stable and Reliable

Snap-on diagonal braces pass through node points, enhancing overall stability and lateral resistance.

Fewer Components, Longer Lifespan: Streamlined design with all parts hot-dip galvanized for corrosion resistance and minimal maintenance.

Flexible Layout, Efficient Assembly: Multiple ledger sizes support various spacing options; the system connects easily for fast and efficient installation.

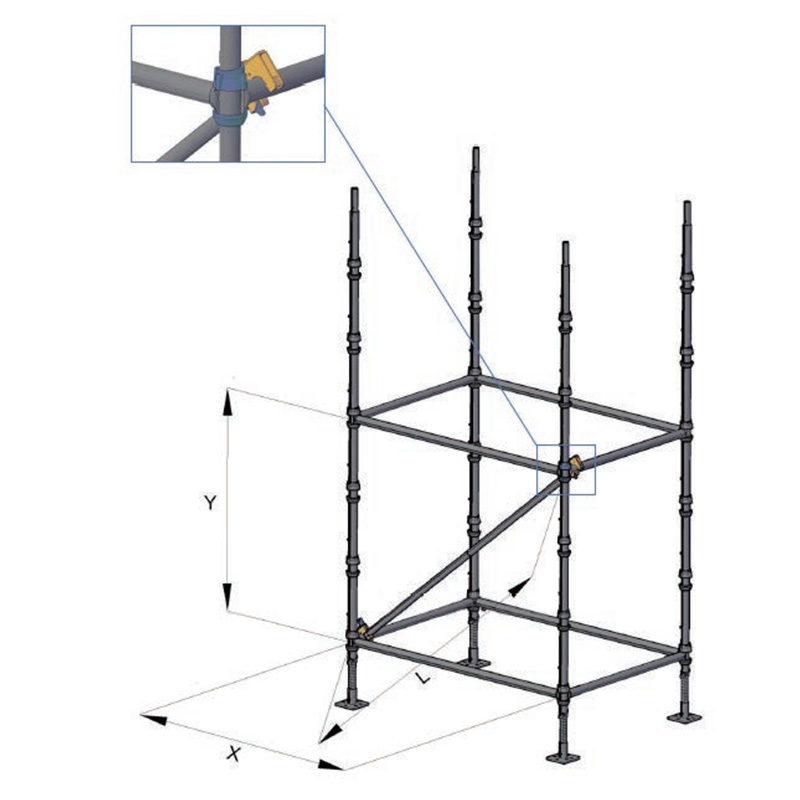

Ringlock Shoring System

The Ringlock Shoring System is widely used in building and municipal engineering projects. When combined with the top formwork bracing rib system, it allows for wider spacing arrangements.

In the Ringlock Shoring System, the standards have a diameter of 60.3 mm with a wall thickness of 3.2 mm, while the ledgers and diagonal braces are 48.3 mm in diameter. All components are made of Q355B structural steel. Compliant with European standards.

Advantages

- High Load Capacity: Single standard supports up to 150 kN.

- Durable Components: Hot-dip galvanized for corrosion resistance and long service life.

- Flexible Design: Multiple ledger sizes for various spacing configurations with strong compatibility.

- Easy Assembly: Quick installation and dismantling with secure connections and diagonal braces.

Considerations for Choosing the Right Construction Support Solutions

In specific engineering projects, the selection of a support system should be based on the project itself, rather than simply pursuing a particular type. It is generally recommended to consider the following dimensions:

- Engineering structure type and construction phase loads

- Support height and span requirements

- Construction cycle and reuse plan

- On-site management and technical support capabilities

Based on these factors, choosing a supplier that can provide systematic solutions and continuous technical support is crucial. Suppliers like Geto, with numerous international case studies and a strong technical background, are more likely to ensure the stable performance of the support system in actual construction.

Conclusion

With the increasing complexity of construction projects, shoring systems in construction are no longer simply temporary supports, but rather crucial systems that impact construction safety, efficiency, and quality. By scientifically understanding different types of scaffold shoring systems, rationally selecting shoring materials, and building construction support solutions that match project needs, construction teams can more confidently handle complex working conditions and provide a solid guarantee for the smooth progress of the project.

Contact the Geto team to get the most suitable, cost-effective, and high-quality shoring system to help you complete your construction efficiently and with high quality.